Hypernetics

Engineering

Hypernetics engineering has expertise in an array of electromagnetic devices. We provide full engineering support from design inception, to prototype build and test, to manufacturing process development through to completion of qualification testing for products such as instrumentation indicators, wheel speed tachometers, proximity sensors and permanent magnet alternators.

We carry out product developments from blank sheet to completion of qualification and release to production with full manufacturing documentation, tooling and fixtures.

We have had customers who have lost the source of an older critical product. Hypernetics has been able to reverse-engineer the product and then manufacture a successful alternate.

Design

The design processes carried out at Hypernetics involve electromagnetic, structural, thermal and reliability analyses to produce candidate designs to meet customer requirements. Test equipment and fixtures required to validate the candidate are also designed by Hypernetics engineering. Full documentation of the design configuration is produced by Hypernetics engineering.

Prototype and Qualification Build and Test

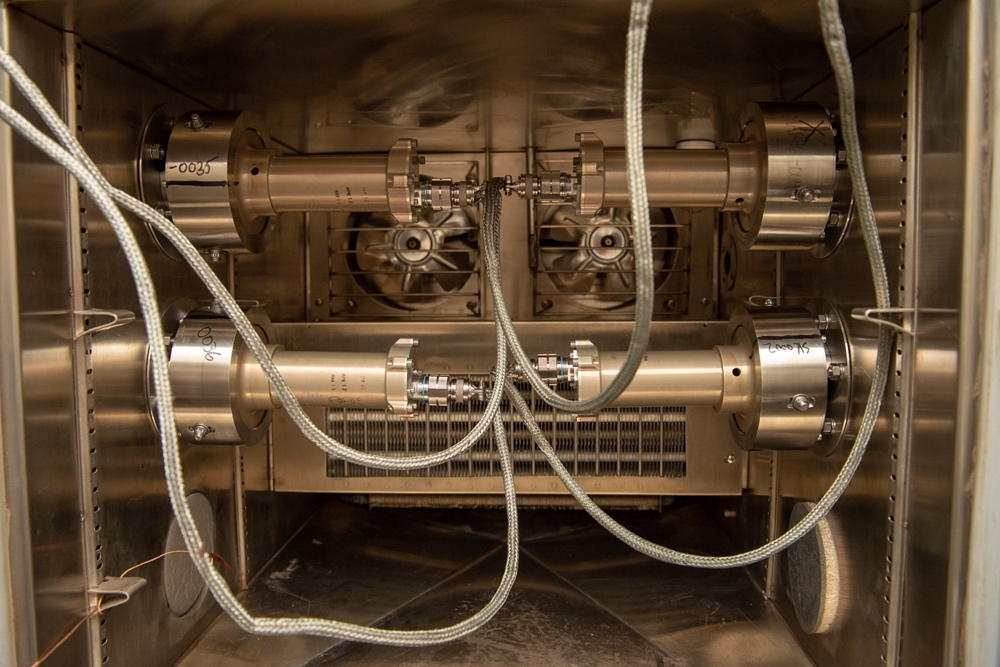

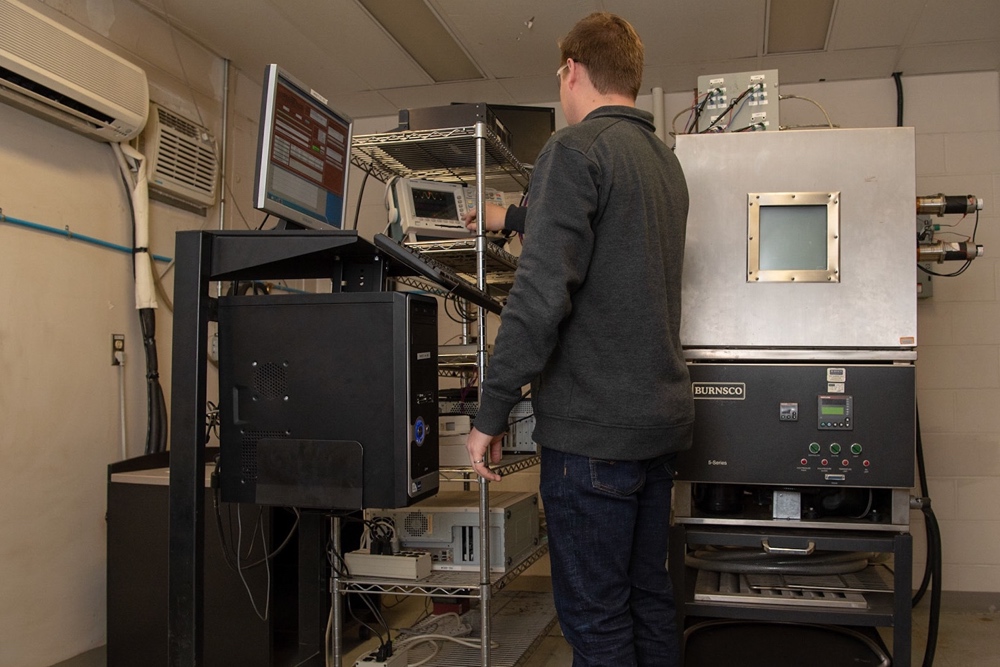

Hypernetics Engineering utilizes Hypernetics Manufacturing to produce both prototype and qualification test units. Engineering carries out the qualification test program using a combination of in-house test equipment (environmental and endurance test chamber, signal performance testing, electrical safety testing) and third party test laboratories (vibration, shock, sand and dust, salt fog etc.)

Production Process Development and Documentation

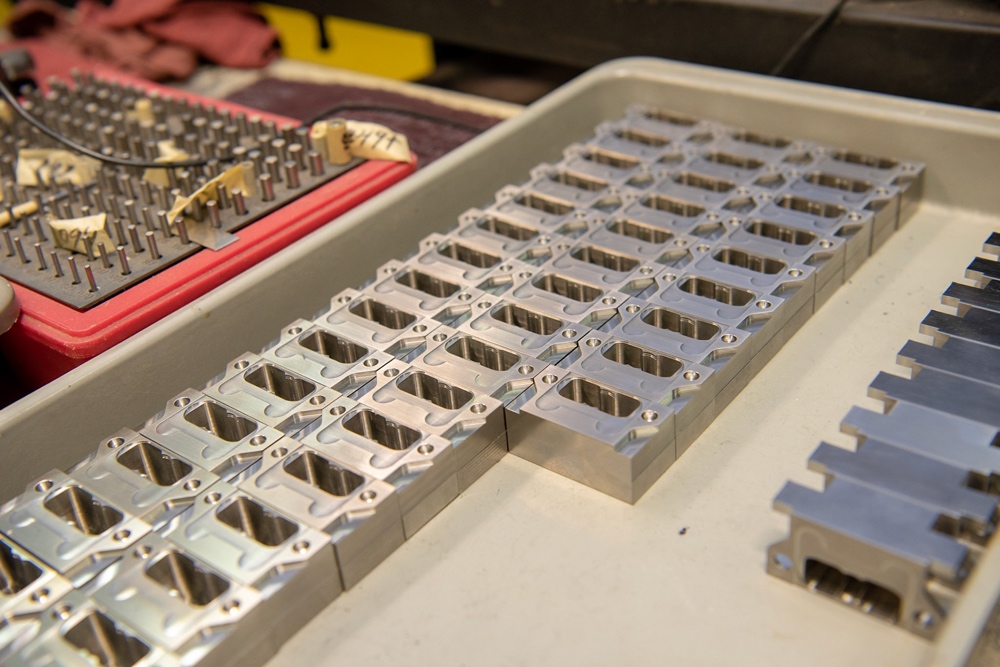

“Build to Print” products often require tooling, fixturing and process development that are not customer supplied. The tooling and fixturing is designed by Hypernetics engineering and built by Hypernetics manufacturing.

Manufacturing

The Hypernetics manufacturing facility has a machine shop and an assembly and test floor.

Some products that we manufacture are “build to print” to customer-supplied manufacturing documentation.

Our other products are Hypernetics designs that are built to manufacturing documentation supplied by Hypernetics Engineering.

The machine shop and assembly floor are used to build prototype products as well as the normal production products.

In House Machine and Model Shop

Our machining capabilities enable fabrication of prototype, first off, and custom volume production. Our expertise includes:

- Precision CNC and manual milling and turning

- Cylindrical and flat grinding

- Stamping and forming

Assembly Processing

Hypernetics offers state of the art manufacturing assembly services. Assembly processing expertise includes:

- Microscope assembly

- Clean cabinet assembly

- Transfer molding

- Laser welding

- Laser marking

- Soldering

- Precision Interconnect

- Flexible PCB

- Miniature point to point